Using any kind of tools or equipment would require some time to learn, and this applies to all people whether they use this equipment professionally or for personal use such as their hobbies or for home improvement. After all, according to the Occupational Safety and Health Administration (OSHA), machine-related hazards are one of the most common mistakes that cause harm.

One machine I want to talk about in particular is the pipe bender. A pipe bender can make bending tubes and pipes easier and simpler. But before you can use one, it’s important to know how to use a pipe bender, the different types of pipes you can use, and the different kinds of pipe benders you may come across whether you’re using one for work or for personal use at home.

Not only will knowing these make your job will be easier to do the next time, but it can also make you more confident and safer when you use it as well as improve the quality of your bent pipes. However, if you still do not completely understand how it works, it’s always a good idea to seek advice from the experts or ask someone more experienced to help you, especially if it is your first time to use it.

What is a pipe bender?

Pipe benders are tools used in a process that’s commonly known as tube bending or pipe bending. This is a permanent process, so trying to return pipes to its original shape can cause it to break or become damaged and reduce its quality. Tube bending doesn’t require pipe benders, but it can greatly help in terms of ease and convenience. Here’s what tube bending looks like without pipe benders to help you.

Pipe benders are tools used to bend pipes and tubes made with various types of material. It can work on different metals such as steel, aluminum, and copper among a few and then formed into different curves and angles.

There are four types of pipe benders: dual pipe, mini pipe, ergonomic, free-standing, ratchet pipe, and conduit pipe. Each of these pipe bender types serves different purposes and produce varying pipe-bending results.

Dual Pipe Benders

This is a manual type of bender with two handles that can bend pipes into different angles, though a 90-degree bend is commonly used for this tool. The pipe is inserted and the two handles are pushed together, causing the pipe to bend.

Because this type of pipe bender is manual, the ability to bend certain types of pipes may be dependent on your strength. Aluminum and plastic pipes may be relatively easier to bend with dual pipe benders but it may be more difficult with materials like steel and cast iron.

Ergonomic Pipe Bender

This manual tool has a longer and curved handle making it easier to bend pipes with less force, but its uses are much more limited. It’s designed to shape only up 10 to 15 millimeter (0.6-inch) pipes and can go up to 180 degrees.

Mini and Micro Pipe Bender

The mini pipe bender is used for pipes that are too small for the dual pipe bender. Its formers are permanently attached to the bender, so you cannot have it changed, unlike other larger pipe benders.

Mini pipe benders have three slots that can hold pipes 6 millimeters, 8 millimeters, and 10 millimeters in diameter. If you have pipes that are still too big, you may have to purchase an even smaller pipe bender known as the micro pipe bender. This can be used with one hand and is often used for electrical systems that require smaller and thinner pipes sized between 3 millimeters to 6 millimeters.

Conduit Pipe Bender

The conduit pipe bender is specifically made for conduit pipes that are used for electrical wires. Unlike other pipe benders, this only has one handle and needs the use of the floor or any flat surface to use as leverage for bending.

Before inserting wires or cables, insert the pipe into the bender and place it on the ground. Using your feet and the floor as leverage, you will then use the handle to bend the pipe. It is recommended that you use conduit pipe benders with longer handles for steel pipes, as the length can give you more leverage.

Do not use the conduit pipe bender if there are wires or cables inside the pipe as the process could damage the wires inside.

Ratchet Pipe Bender

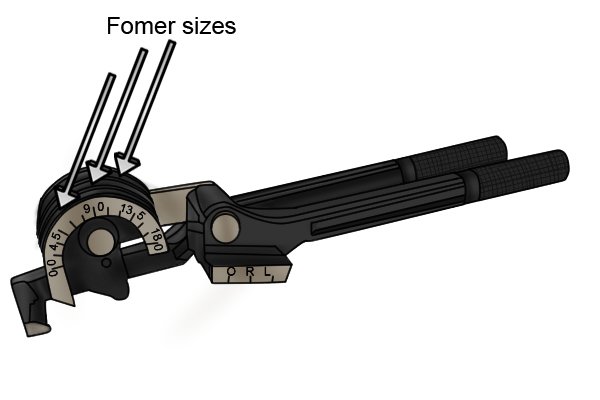

Instead of using your own force to bend pipes, ratchet pipe benders have a lever that pushes the former into the pipe to bend it inwards. Because of this, its structure looks different from other pipe benders and can only bend up to 90 degrees.

This is good for projects that involve limited space and other types of pipe benders may not be appropriate or usable. Ratchet pipe benders can handle pipe sizes between 10 millimeters up to 32 millimeters.

Free-Standing Pipe Bender

The largest pipe bender of the bunch, free-standing pipe benders have two legs that allow you to easily bend larger and thicker pipes with both hands. The increase pressure exerted by the user can help bend pipes made with stronger materials.

How to use a pipe bender

Here are some tips of using a pipe bender so you will be properly-equipped with enough knowledge and skills for your future bending projects.

1. Learn the right measuring technique.

When measuring pipes to be bent, it is important to determine the center and use it as a base point. It will also help locate the exact pipe area that will be bent and ensure that the bending procedure is done in equal measurement.

2. Practice on bending.

Try bending practice pipes first and attempt to bend in different angles. Make sure you learn how to bend them without stressing and even hurting yourself at work. Pipe bending is supposed to be done fast and smoothly.

3. Avoid the occurrence of tube crimping.

Crimping commonly occurs on lighter materials such as aluminum. Such kind of materials tends to crimp when bent. To avoid this, fill it with water and sand. With a tapping motion, gently move the sand around. It will then form air bubbles and make your pipe bending procedure easier.

Pipe bender maintenance tips

Here are some tips to ensure your pipe bender’s optimum condition and performance.

- Apply lubricant to the joints of the pipe bender, particularly to its handle joints and roller. This will help loosen the equipment and make the bending job easier.

- Avoid using a damaged bender or if any of its parts are lacking. Make sure to have the tool repaired first before using it again.

- When not in use, make sure to clean it well and store in a non-humid and clean area. Keep it out of reach of children and other unauthorized persons.

Pipe Bender Safety Tips

Like any other hardware tool or equipment, pipe benders pose a risk when in use. It’s important to exercise caution when using pipe benders, so be sure to follow these safety tips.

- Use personal protective equipment when operating. There’s always a risk of pipes breaking if you’re not careful, so it’s best to wear the appropriate attire when working on a project. These include pants, close-toed shoes, thick, long-sleeved shirts, goggles, and insulated gloves.

- Check your pipe benders before every use. Never use pipe benders with clear damages or defects.

- Keep your hands away from the former especially when in use.

- Do not exceed the capacity or pipe size stated by your pipe bender’s manufacturer.

- Do not use the pipe bender for any other purpose than it was meant for.

- Read and understand the user manual before using the pipe bender. If you’re unsure, get someone more experienced to show you how to use it.

- Clean your pipe regularly and keep it well-lubricated.

- After use, clean your pipe bender and store it in a clean and non-humid location like your garage. If you plan on using it again, it helps to re-lubricate your pipe bender and check for any damage.

Conclusion

Pipe benders are not necessary for the process of tube bending. However, if you look at the different DIY ways done, you may see why they’re a highly recommended tool to have.

Pipe benders get the job done easier and more conveniently, and pipe benders are designed to help you bend your pipes at the right angle you need. If you’re trying to bend a pipe without a pipe bender, you’ll only be eyeballing it and estimation. And if you estimate incorrectly, it can be costly and time-consuming, especially if you have to buy more pipes to re-do the pipes you’ve bent too much and can no longer be used for your project.

All in all, pipe benders are a useful tool for anyone working professionally, personal home improvements, or even for those who love crafting as a hobby. Pipe benders may be an added cost on your part, but you can make it an investment that you get back in terms of accuracy, speed, ease, and convenience.